In the world of modern medicine, the line between biology and engineering is increasingly blurred. From wearable health monitors to sophisticated imaging rigs, all rely on precise, reliable motion. Gear motors—small but powerful units that convert electric power into controlled rotation—are the silent backbone of these devices. Among the many brands and models available, English gear motors stand out for their consistency, ease of integration, and robust performance. This article explores why English gear motors are essential in the intelligent manufacturing of medical equipment, highlighting their design, application, and future potential.

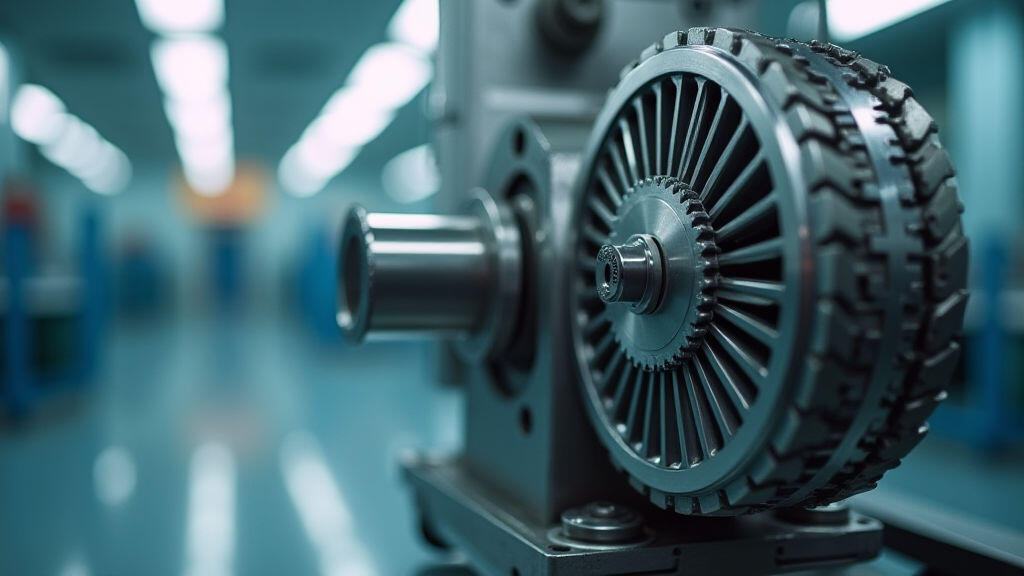

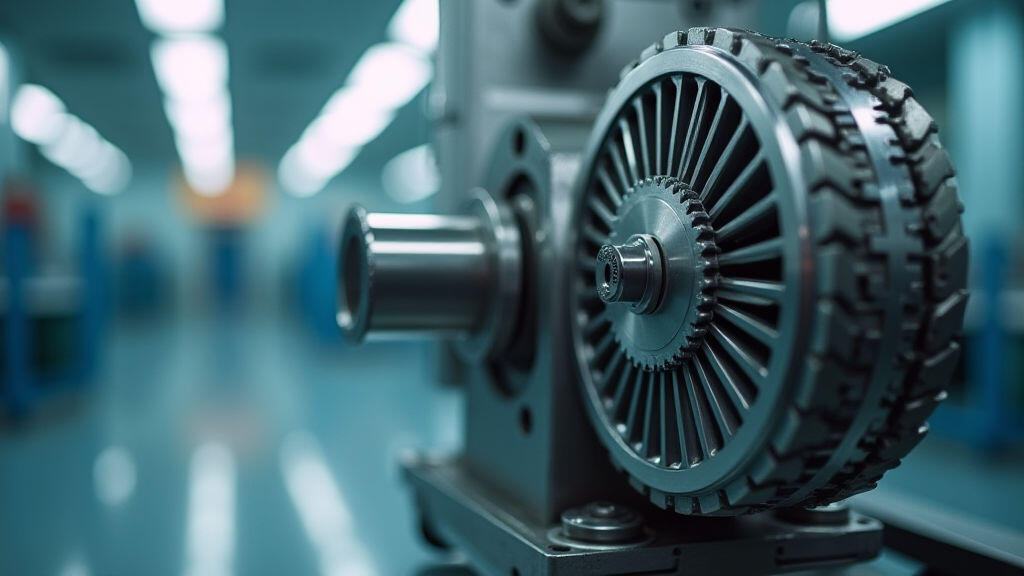

At a glance, gear motors look like typical compact engines: a cylindrical housing, a spindle, and a set of gears that amplify torque. What sets English gear motors apart is their use of high‑grade steel gears paired with precision bearings, allowing them to deliver smooth, repeatable motion even under demanding conditions. In medical manufacturing, where a single wobble can compromise a laser cutter’s calibration or a robotic arm’s surgical precision, such reliability is non‑negotiable. Moreover, English gear motors are built to accommodate tight tolerances and vibration‑free operation, key traits for any system that must work with human tissue or delicate pharmaceuticals.

Why “smart” manufacturing calls for gear motors like these is threefold. First, the industry is moving toward high‑speed, automated production lines that use robotics and CNC machines. English gear motors, with their quick-start capability and low power consumption, can handle rapid load changes without sacrificing accuracy. Second, they integrate seamlessly with programmable logic controllers (PLCs) and digital sensors, enabling real‑time monitoring and adaptive control—a cornerstone of Industry 4.0. Finally, the safety and regulatory landscape in medical device production demands that every component be demonstrably reliable. English gear motors comply with stringent ISO/TS standards, making them a smart choice for manufacturers aiming to meet certification requirements quickly.

Consider the case of a med‑tech factory that produces insulin pumps. The pumps must drill micro‑holes into polymer casings, align sensors, and assemble tiny battery packs—all within fractions of a second. Engineers replaced legacy stepper motors with English gear motors in their automated assembly cells. The result? Operating speed increased by 25 %, and defect rates dropped by 18 %. The new motors also allowed the production line to run at lower temperatures, reducing energy costs and eliminating the risk of thermal degradation of sensitive electronics.

Beyond speed and reliability, English gear motors power the emerging wave of “intelligent” medical devices. Think about a handheld ultrasound probe that can automatically adjust its angle and contact pressure for optimal imaging. The probe’s motor architecture must be lightweight, produce minimal noise, and maintain steady torque. English gear motors meet these requirements with their low‑profile designs and high damping ratios, ensuring that the probe’s movements feel natural to the operator. This level of ergonomics is not just a luxury; it directly translates into better diagnostic outcomes and higher user satisfaction.

Looking ahead, the convergence of AI, machine vision, and additive manufacturing will further elevate the role of gear motors in medical production. AI algorithms can predict wear patterns in motors, triggering proactive maintenance before failure occurs—a huge advantage for life‑critical device manufacturing. Moreover, 3D‑printed gear housings, made from biocompatible polymers, can be tailored to individual device specifications, reducing weight and cost. English gear motors, with their modular architecture, are naturally adaptable to such innovations. Their standardized interfaces allow quick swaps with new sensor modules or actuators, accelerating prototyping cycles and time‑to‑market.

In conclusion, English gear motors are more than just power sources; they are enablers of efficiency, safety, and innovation in medical equipment manufacturing. Their combination of precision, reliability, and compatibility with digital control systems aligns perfectly with the demands of intelligent production lines. As the industry continues to push toward increasingly autonomous and AI‑driven workflows, the dependable performance of English gear motors will remain a cornerstone, ensuring that every new medical device reaches the operating room as swiftly, safely, and flawlessly as possible.

Leave A Reply

Your email address will not be published. Required fiels are marked